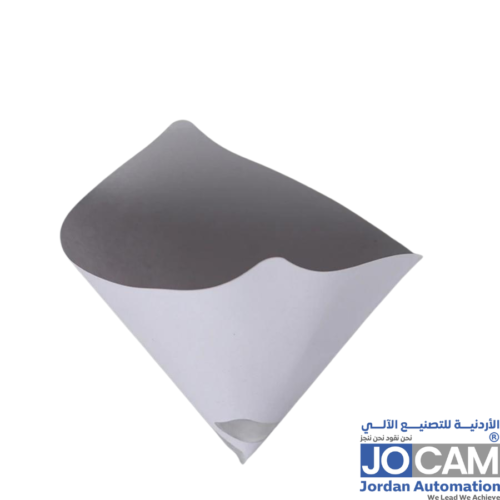

8k Resin for 3D Printer Grey Color

50.000 د.ا

8k Resin for 3D Printer Grey Color

Rigid 3D Printer Resins

Standard Pro 12k 3D resin is an upgrade from 8K standard resin, enhanced the toughness which is not that crispy, and well compatible to all 385-405NM 3D printer.

Upgraded Toughness and Durability

Experience robust, impact-resistant creations, It has 15.26±10%

elongation at break, which is double the toughness compared to the first-generation standard resin and nearly 50% less brittleness.

The perfect balance between stiffness, impact resistance and flexural strength provide good protection for your printed models .

Did you like this product? Add to favorites now and follow the product.

Description

8k Resin for 3D Printer Grey Color

Jamg He rigid 3d printer resin cures quickly, has excellent toughness, and maintains good hardness.

UV curable 3d printing resin prints models with perfect details, high surface finish, and is easy to paint, making it ideal for printing miniature models.

Jamg He LCD Standard Plus Resin

Low Smell & Viscosity

Jamg He LCD Standard Plus Resin is eco-friendly, solvent-free, with low odor & viscosity.

It reduces environmental impact and enhances user comfort. Its low viscosity ensures a smoother printing process and finer model surfaces.

Standard Resin for 3D Printer Black Color

What defines Resin 3D printing?

- they use a principle of photopolymerization to create objects;

- they operate according to a code (or a machine creates a code straight from an uploaded digital model);

- as a material, they use UV or daylight resins (photopolymers);

- the material is stored in a vat (bath/resin tank).

Photopolymerization is a chemical reaction of a liquid material that changes its properties when subjected to light (UV, laser, etc.). The scientific term for such liquids is photopolymers or light-activated resins, and in 3D printing, they are just referred to as resins.

How Resin printers form an object?

Resin 3D printers can form an object normally or upside down, depending on how the components are positioned inside the machine and whether the build platform drops down or lifts up. Upside-down orientation is more common for desktop machines because it’s easier to operate and fabricate without losing out on quality. The critical factor with upside-down resin printers is the print adhesion and supporting structures, preventing a part from falling down due to gravitational pull.

Additional information

| Weight | 1 kg |

|---|

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.